The Badger

Advantage

Engineered rugged and tough from the inside out, Badger shredders reduce larger abrasive materials than any crusher in its class with more efficiency and throughput. Designed with exclusive reconfigurable shaft blades, the Badger provides versatility that no other crusher can match. Its high-torque, low-speed shaft design can be configured to shred whatever your job demands. And, it shreds with less noise pollution and dust than ever before.

Longer Lasting, Stronger Materials

Superior Quality

Shredding Chamber

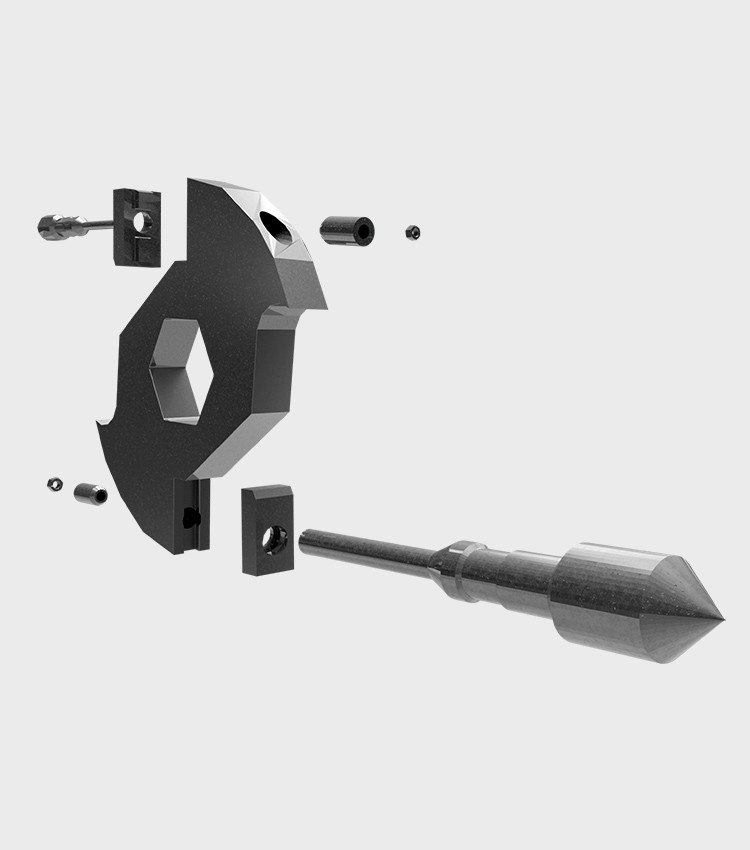

Replaceable Blades & Bits

Blades are fabricated from heavy-duty high-strength steel and are individually mounted to twin shafts. Replaceable wear parts are easily changed, prolonging the life of the shredding blades.

A weld-less hexagonal blade shape fits precisely to the shaft and provides the ultimate positive drive and strength.

Long Running

Lower Maintenance Costs

The Badger is engineered for low-cost operation over the life of the machine. The machine runs at a low speed and ramps up RPMs only when additional power is required to shred tough materials.

Exclusively designed with replaceable counter knives, the shredder maximizes machine life and efficiency. This design reduces material build-up and prevents debris tangling while providing a second-stage shredding effect.

More Power & Torque

Powered By Volvo

Diesel-powered Badger models are powered by an ultra-reliable Volvo D16 powertrain that provides the Badger ample power to eat through whatever materials you can feed it. The high-torque drivetrain features a low engine speed and straightforward design that reduces service intervals and cost of operation.

Hydraulic Power System

Smart Technology

Configurable

Blade Versatility

Badger pioneered the ability for operators to replace or reconfigure their blade shafts for any shredding need. Unlike conventional crushers, the Badger’s shaft assemblies can be dismantled and reconfigured on the job site or at the shop to accommodate any shredding need, job by job. No welding, no grinding.

Custom interchangeable helix angles between the blades provide exclusive shred options unique to the Badger shredding system.

Safety

Operate Remotely

An optional remote control system provides full shredder maneuverability and functionality when working in hazardous and multi-unit feed environments. Retain smooth and precise machine control from across the job site. An ICAN smart control system provides automatic safety control.

Subtitle

Warranty & training

All components used in the manufacture and fabrication of Badger shredders are selected for their reputation of quality and aftermarket availability. Should you encounter an issue with your Badger, the unit is covered by a (12) month / 1,000 hour limited warranty. The Factory can also access your Badger remotely for diagnostics and troubleshooting. Upon delivery, a Factory Representative will arrive on-site, providing operation and maintenance demonstrations.

A parts and consumables guide is also provided. This guide outlines essential parts to keep on hand to maintain optimal running efficiency and uptime.

Field

Tested

Badgers are tested and proven in real-world conditions and harsh extremes.

Durability & Reliability

Engineered to provide unmatched shredding performance your jobsite can rely on.

Improved Engineering

Manufactured in the USA to deliver superior production advantages & greater ROI.

Smart

Technology

Changing the way the industry applies heavy equipment technology - from efficiency to safety.

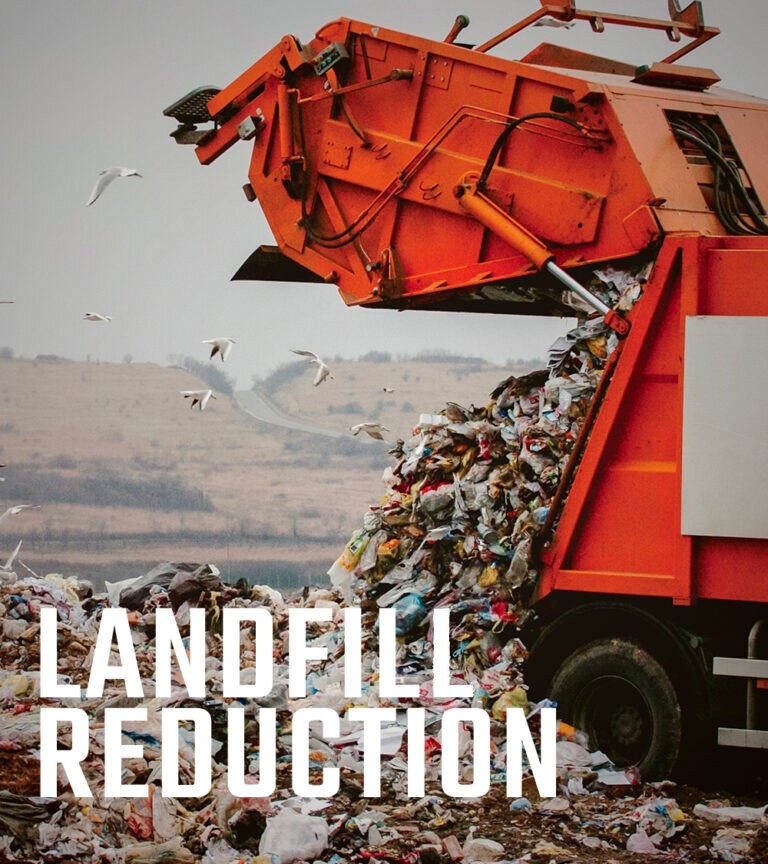

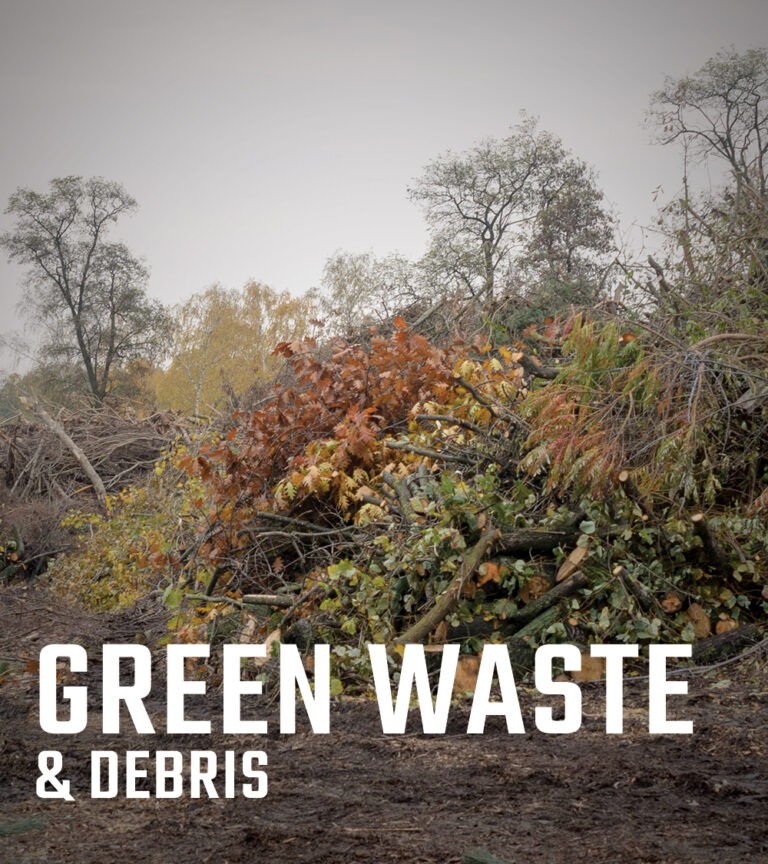

Application Versatility »

The Badger twin shaft, slow speed, high torque shredding machine represents a new evolution in recycling. By incorporating innovative new-to-market features and benefits, Badger has the versatility to shred more types and sizes of materials than anyone else.